What is a Portable Classroom?

A portable classroom (also called a demountable or relocatable classroom) is a modular, prefabricated space for schools needing extra room fast. These buildings go up quickly and move just as easily when no longer needed.

Built with the PortaPack system, which combines off-site manufacturing with on-site assembly, they minimize disruption and are ready to use fast. Perfect for growing schools, remote learning hubs, community workshops, or emergency training centers, they work like permanent buildings—without the long wait.

Made from eco-friendly materials and meeting international safety standards, they’re durable, energy-efficient, and fully adaptable. With built-in tech, climate control, and custom layouts, they’re a smart solution for modern education.

Why Choose Modular Classrooms?

We address traditional school challenges with smart, compassionate solutions:

- Speed vs. Construction Delays

Permanent expansions take months; our modular classrooms deploy in 3-4 weeks, solving overcrowding for both temporary and long-term needs. - Specialized Support for Diverse Learners

Unlike standard classrooms, we offer Portable Sensory Rooms with adjustable lighting, soundproofing, and tactile zones to support neurodiverse students. - Unmatched Customization

Tailor every detail: dimensions (3m–30m+), ceiling heights (up to 4.5m), STEM lab layouts, or accessibility features—far beyond rigid traditional designs. - Zero On-Site Disruption

Traditional renovations disrupt learning; our 90% prefabricated components allow schools to manage assembly independently, ensuring uninterrupted operations. - Adaptable Lifespan

Repurpose classrooms effortlessly—expand into libraries, labs, or community centers without demolition, unlike permanent brick-and-mortar constraints.

Precision-engineered for education’s evolving needs. From preschools to senior learning hubs, we blend ISO-certified quality, rapid deployment, and inclusive design to create spaces that grow with you.

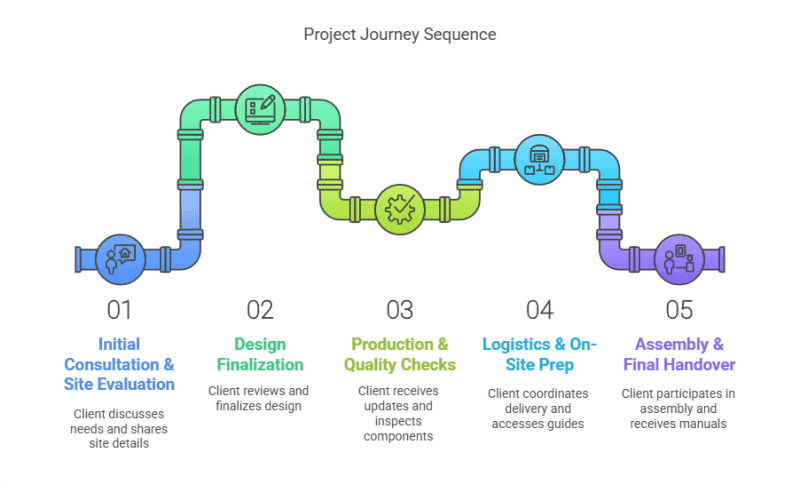

Step-by-Step Portable Classrooms Journey

We keep you informed and involved at every milestone—here’s how it works:

1. Initial Consultation & Site Evaluation

Timeframe: 1-2 days

Client Involvement:

- Video conference to discuss enrollment needs, budget, and site specifics (e.g., terrain, utilities).

- Share site photos/blueprints via our portal for initial feasibility assessment.

Deliverables: - Preliminary 3D layout proposal with cost estimate.

2. Design Finalization (3 Interactive Reviews)

Timeframe: 5-7 days

Client Involvement:

- Review 1: Virtual walkthrough of 3D model to adjust dimensions, window placements, and accessibility features.

- Review 2: Material selection (e.g., wall insulation grades, door/window styles) via sample kits and live demos.

- Review 3: Compliance checklist sign-off (local fire codes, ADA requirements).

Tools Used: BIM software screensharing, real-time annotation for feedback.

3. Production & Quality Checks

Timeframe: 4-6 weeks

Client Involvement:

- Weekly video updates from the factory floor (e.g., steel framing progress, panel installations).

- Pre-shipment virtual inspection: Verify component labeling, bolt-hole alignment.

Key Checks: - Welding integrity (ISO 5817 standards).

- Fireproofing spray thickness (meeting ASTM E119).

4. Logistics & On-Site Prep

Timeframe: 1-2 weeks

Client Involvement:

- Coordinate delivery schedule with your local team.

- Access our Site Prep Guide (grading, foundation templates) via video tutorials.

Included: - Customs clearance support for international orders.

- Damage report protocol for received components.

5. Assembly & Final Handover

Timeframe: 1-2 weeks (depending on crew size)

Client Involvement:

- Daily 30-minute video check-ins with our engineers to troubleshoot assembly steps.

- Final walkthrough via live stream to confirm HVAC, electrical, and safety systems.

Post-Support: - Digital O&M manuals (multilingual) with maintenance schedules.

What’s in Your Portable Classrooms Package?

Your portable classroom package includes:

| Items | Specifications |

| Main Steel Frame | Galvanized steel (ASTM/AISI certified) |

| Secondary Frame | Corrosion-resistant cold-formed steel |

| Span | 6m-12m |

| Height | 3m-4.5m |

| Length | 6m-30m |

| Width | 3m-9m |

| Roofing Systems | Insulated waterproof panels (PU/PIR core) |

| Wall Systems | Fireproof sandwich panels (EPS/rock wool) |

| Structure Add-ons | Partitions, ramps, canopies |

| Door | Steel/glass doors (fire-rated options available) |

| Windows | Double-glazed PVC/aluminum (sliding/fixed) |

| Connection Form | Pre-drilled bolt-on assembly |

| Customization Options | Size, layout, color, pre-installed utilities |

| Building Usage | Classrooms, offices, labs |

| Construction Time | 2-4 weeks |

| Temperature Range | -30°C to 50°C |

| Processing Service | Custom cutting, welding, OEM support |

Trusted Portable Classroom Manufacturer: Quality Without Compromise

While we don’t offer on-site installation, our team provides step-by-step remote guidance—from foundation prep to final inspections—to ensure smooth assembly by your local contractors.

Unique Manufacturing Strengths:

- Cost-Effective Modular Kits: Pre-cut, pre-drilled components reduce material waste and labor costs by 20-30% vs. traditional builds.

- All-Weather Durability: Reinforced joints and anti-corrosion coatings extend lifespan to 25+ years, even in coastal or high-humidity regions.

- Local Code Compliance: Pre-engineered to meet regional safety standards (e.g., seismic zones, fire codes) across 15+ countries.

- Streamlined Logistics: Flat-pack shipping minimizes transport costs, with 95% of orders delivered damage-free.

We’re committed to making portable classrooms accessible, reliable, and simple—no cutting-edge gimmicks, just proven solutions that work.

FAQs

- Can your modular classrooms support air conditioning, heating and other equipment?

- Yes, our classrooms have reserved interfaces for air conditioning, power supply, lighting, etc., and you can install air conditioning, heating, ventilation system, and lighting facilities by yourself.

- How is the sound insulation effect of modular classrooms? Is it suitable for teaching environment?

- Our classrooms use high-performance sound insulation walls (optional double-layer structure), which can effectively reduce external noise interference and ensure a quiet learning environment. For music rooms or classrooms with special needs, additional sound insulation layers can be added.

- Can your modular Classrooms be stacked or expanded into multiple classrooms?

- Yes. Our modular system supports single-layer or multi-layer (up to 2-3 layers) stacking, and multiple modules can be connected to form a larger teaching space.