The basic structure of our steel barn

Main frame

Our steel structure warehouse (steel barn) uses ASTM A572 Gr50 high-strength steel (yield strength ≥345MPa) as the main supporting material, which has excellent earthquake and wind resistance, adapts to various environmental conditions, and ensures long-term and stable use of the warehouse.

Walls and roofs

The walls and roofs are covered with double-sided 275g/m² hot-dip galvanized steel plates or color steel plates, which have excellent anti-rust and anti-corrosion properties.

The thickness of the galvanized layer exceeds the ISO 1461 standard by 2.1 times, which greatly enhances the durability of the material, extends its service life, and can resist severe weather, chemical corrosion and other environmental influences.

Our Metal Barn types

We provide a variety of design solutions to meet different site requirements and usage functions. Common steel structure warehouse designs include:

1. Classification by purpose

Agricultural Steel Barns: Mainly used for storing grain, feed, agricultural machinery and equipment, etc., characterized by a large span, equipped with a good ventilation system to prevent grain from getting damp, and optional insulation layer to regulate the internal temperature.

Livestock Steel Barns: Used to raise livestock, such as cattle, horses, sheep, etc., the design focuses on ventilation and drainage systems to ensure the comfort of livestock, facilitate cleaning and maintenance, and reduce the risk of disease transmission. Optional insulation layer to adapt to extreme climates.

Storage Steel Barns: Used to store goods, equipment or other items. It is characterized by large space and solid structure to ensure the safety of stored items, and can customize compartments or shelves according to needs.

Multi-Purpose Steel Barns: Can be used for a variety of purposes such as garages, workshops, exhibition halls, etc. Flexible design, strong adaptability, optional doors, windows, lighting and other facilities to improve convenience.

2. Classification by structural design

Single Slope Steel Barns: The roof is tilted to one side, which is convenient for drainage. The structure is simple and the cost is low. It is suitable for small farms or storage purposes.

Gable Steel Barns: The roof is triangular and symmetrical on both sides, providing a larger internal space. It is suitable for medium to large farms or storage purposes.

Quonset Steel Barns: The roof is semicircular, compact, and has excellent wind resistance. It is suitable for areas with harsh climates, and it is quick to install and low in cost.

Multi-Span Steel Barns: It consists of multiple spans, suitable for large farms or commercial purposes, providing a large internal space, suitable for storing large equipment or a large amount of goods, and can be expanded according to needs.

3. Classification by functional configuration

Standard Steel Barns: Basic configuration, suitable for general storage needs, low cost and quick installation.

Premium Steel Barns: Equipped with advanced features such as insulation, ventilation system, intelligent monitoring, etc., suitable for customers with high requirements for environment and safety.

Custom Steel Barns: Customized size, design and function according to customer needs, suitable for customers with special needs.

4. Classification by scalability

Fixed-Size Steel Barns: Fixed size, suitable for one-time needs, fast installation and low cost.

Modular Steel Barns: Supports later expansion, customers can increase area or function according to needs, suitable for customers who need flexible adjustment.

Advantages of our Steel Barn

- Durability: The high strength of steel and galvanized protection ensure long-term use of the product in harsh environments.

- Low maintenance cost: Almost no maintenance is required and it is not affected by pests, mold or corrosion.

- Quick installation: Prefabricated components and modular design greatly shorten construction time.

- Environmental protection: Steel is 100% recyclable, reducing the impact on the environment.

- Column-free large span: The maximum clear span is 36 meters (the column spacing is reduced by 43% compared to traditional structures), providing a larger internal space, suitable for storing large equipment or mechanized operations.

- Self-draining system: 12° standard roof slope + 300mm wide integrated water guide channel.

- Foundation adaptation: The pre-punched ground beam system can adapt to ±50mm ground unevenness.

Customized options

Size and appearance: The facade of our steel structure warehouse can be selected in a variety of sizes and personalized coatings to ensure harmonious integration with the surrounding environment.

Specialized functional configuration for agriculture

- Ventilation efficiency: Equipped with ridge turbine ventilator (diameter 600mm) and side wall electric shutters to achieve full warehouse air replacement (5 times per hour), ensure good ventilation, effectively prevent moisture and odor, and create a healthy storage environment.

- Humidity control: Adopt 0.1mm aluminum foil insulation pad to effectively reduce condensation water generation, reduce the impact of moisture on items, and keep the environment dry.

- Bird-proof design: 30mm eaves folding design, and reserved ultrasonic bird repellent installation slot, effectively avoid bird intrusion and ensure warehouse safety.

- Insulation layer: Insulation materials can be selected according to needs to help regulate internal temperature, adapt to extreme climate conditions, and maintain a stable storage environment.

- Solar panel roof: Optional solar panel roof, combined with renewable energy, helps green buildings, achieve energy self-sufficiency, and reduce operating costs.

Modular expansion system

- Basic unit: The standard module size is 12m (width) × 30m (length) × 6m (eave height), which is suitable for most basic needs.

- Extension method: Supports two-way extension in multiples of 8m, and the length and width can be expanded independently, providing a flexible space management solution for future expansion.

Technical Specifications

Surface Treatment Process

- Optional Coatings: We offer RAL standard color electrostatic powder coating, providing excellent corrosion resistance and weatherability. It has passed the 2000-hour salt spray test, ensuring long-lasting appearance and performance.

- Wear-Resistant Flooring: The flooring is made of 2mm thick diamond-patterned steel plate (Shore hardness 85D), offering outstanding wear resistance, making it suitable for high-intensity environments and ensuring long-term durability.

- Corrosion Protection Layer: A 1.2mm polyurethane liner is available as an option, providing resistance against 20% ammonia gas corrosion, making it ideal for agricultural and chemical environments, extending the lifespan of the structure.

Measured Load Capacity

- Wind Resistance: The structure has been tested for 0.55 kN/m² equivalent wind pressure (corresponding to a wind speed of 44.6m/s), demonstrating excellent wind resistance, suitable for various weather conditions.

- Lifting Points: The roof is equipped with 6 pre-installed lifting points, each with a static load capacity of 5 tons, facilitating equipment installation and maintenance.

- Ground Load Bearing: The standard version has a ground load capacity of 3 tons/m², which can be reinforced up to 8 tons/m² to accommodate higher storage requirements.

Prefabrication Precision Standards

- Component Tolerance: Our steel structure components are manufactured with high precision, with beam and column length tolerance ≤ 1.5mm/6m, ensuring efficient and precise installation.

- Hole Position Accuracy: We use laser-guided pre-drilled holes, with installation cumulative error < 2mm, significantly improving ease of construction and accuracy.

- Waterproofing: The roof panel overlap is treated with 3M™ AC-257 sealing tape, ensuring long-lasting waterproofing performance.

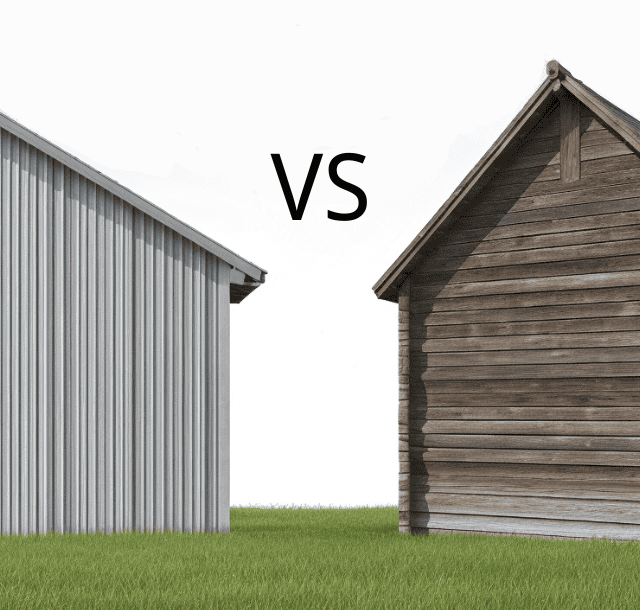

Steel Barn vs Wood Barn

| Feature | Steel Barn | Traditional Wooden Barn |

| Durability | High, resistant to corrosion and pests | Low, susceptible to pests and moisture |

| Maintenance Cost | Low, requires almost no maintenance | High, requires regular upkeep and repairs |

| Installation Speed | Fast, prefabricated components, short construction time | Slow, long construction period |

| Environmental Impact | High, steel is recyclable | Low, wood consumption is high |

| Fire Resistance | Excellent, steel is non-flammable | Poor, wood is highly flammable |

| Lifespan | Long, typically over 50 years | Shorter, usually 20-30 years |