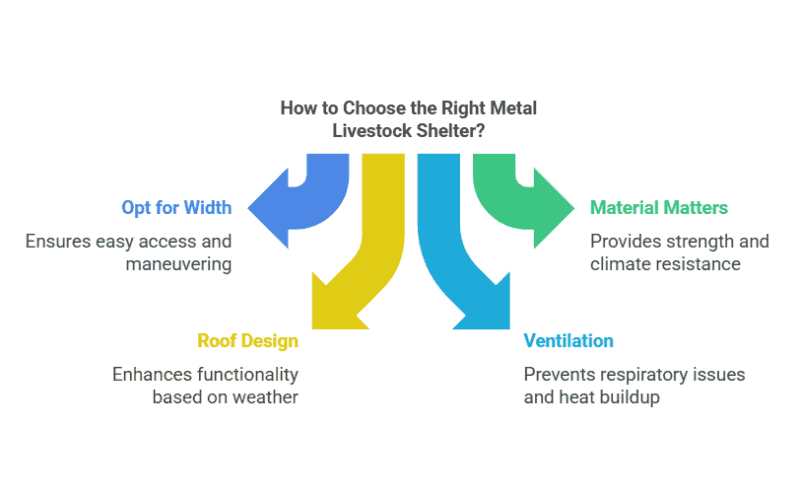

How to Choose the Right Metal Livestock Shelter

As a structural engineering specialist, I recommend prioritizing these factors when selecting livestock barns and shelters:

Opt for Width Over Depth

For metal horse shelters or cow shelters, choose a structure 20-30% wider than your herd size requires (e.g., 12m x 6m instead of 9m x 8m). This prevents dominant animals from blocking narrow entrances and allows timid livestock to access feed and water freely. Wider layouts also simplify equipment maneuvering in livestock buildings.

Material Matters: Balance Strength and Climate Resistance

Select G550 steel with AZ150 coating for high snow-load regions (≥1.5kN/m²) or coastal areas. For arid climates, galvanized steel (Z275) paired with anti-UV coated panels reduces heat absorption by up to 40%. Avoid thin-gauge steel (<0.4mm) for large steel arch buildings housing cattle—opt for 0.5-0.7mm walls to withstand rubbing and kicking.

Roof Design Dictates Functionality

Gable roofs (30° pitch): Ideal for metal animal shelters in heavy rainfall/snow zones, enhancing water runoff.

Single-slope roofs: Perfect for attaching to existing barns, providing cost-effective shade for poultry or goats.

Arched designs: Best for wind-prone areas, reducing wind pressure by 25% compared to angular structures.

Customize Ventilation Based on Species

Install adjustable side vents (30-50cm height) for horse shelters to prevent respiratory issues, while cow shelters benefit from continuous ridge vents to dissipate heat and ammonia. For mixed-use livestock buildings, zone-specific airflow systems optimize comfort.

Future-Proof Your Investment

Choose modular designs that allow easy expansion—e.g., a 10m x 5m metal horse shelter can extend to 15m with pre-engineered connectors. SteelPRO PEB’s 3D configurator lets you visualize how each specification impacts daily operations, from feed cart access to veterinary workflows.

Pro Tip: Always request a site-specific wind/snow load report—this ensures your shelter’s frame thickness (e.g., 2.5mm vs. 3.2mm columns) matches regional weather risks.

Our Metal Livestock Shelter Specifications

| Items | Material | Specifications |

| Main Steel Frame | G550 steel, Q345B steel | – Hot-dip galvanized (AZ150/Z275 coating) <br> – Column thickness: 2.5mm–5.0mm |

| Secondary Frame | Z275 galvanized steel, S235JR | – Purlin thickness: 1.5mm–2.5mm <br> – Truss spacing: 1.2m–2.4m |

| Span | / | 6m / 12m / 18m / 24m / 30m (adjustable for large steel arch buildings) |

| Height | / | 3.5m / 4.2m / 5.0m / 6.0m / 7.5m (optimized for cow shelters & ventilation) |

| Length | / | 10m / 15m / 20m / 25m / 30m+ (expandable for livestock barns and shelters) |

| Width | / | 6m / 9m / 12m / 15m / 18m (wider designs for horse shelters to reduce dominance) |

| Roofing Systems | DX51D+AZ150 steel, PPGI | – 0.5mm–0.7mm thickness <br> – Slope: 5°–30° (snow/rain runoff optimization) |

| Wall Systems | PU sandwich panels, EPS core | – 50mm–100mm insulation <br> – Corrosion-resistant coating (1200D polyester) |

| Structure Add-ons | Q345B steel, S355JR steel | – Wind bracing (for spans >18m) <br> – Snow guards (1.5kN/m² capacity) |

| Door | Galvanized steel (Z275), Aluminum | – Sizes: 3m(W)x3m(H) to 6m(W)x4.5m(H) <br> – Optional automatic sensors |

| Windows | Polycarbonate, Tempered glass | – 30cmx60cm to 1.2m x 2.4m <br> – Adjustable angles for ventilation control |

| Connection Form | / | – M16–M24 high-tensile bolts <br> – Seam welding (3mm fillet) for rigidity |

| Customization Options | / | – Skylight (1m x 1m panels) <br> – Partition walls <br> – Ventilation flaps |

| Building Usage | / | – Metal horse shelters / cow shelters / poultry houses <br> – Feed storage |

| Construction Time | / | 10–25 days (e.g., 12m x 6m shelter = 12 days) |

| Temperature Range | / | -40°C to +120°C (ideal for livestock buildings in extreme climates) |

| Processing Service | / | – CNC laser cutting (±1mm tolerance) <br> – Pre-punched holes for fast assembly |

Shipping & Delivery Details

| Item | Description | Details |

| Packaging | Wooden crates / Containers | – Crates: For loose components (ISPM15 compliant) <br> – Containers: FCL/LCL for cost efficiency |

| Shipping Ports | Main export hubs | Qingdao / Dalian / Tianjin / Ningbo (other ports negotiable) |

| Delivery Time | Standard lead time | 4–8 weeks: <br> – 4–6 weeks for pre-engineered shelters <br> – 6–8 weeks for customized designs |

| Transportation Modes | Sea / Rail / Road | – Qingdao/Dalian: Primarily sea freight <br> – Inland cities: Rail or truck |

Installation Guidelines for Your Metal Livestock Shelter

Ensure a smooth setup for your livestock barns and shelters with these professional tips:

- Team & Time Allocation

- Basic Structures: A team of 2–3 skilled workers can assemble a standard metal horse shelter or cow shelter in 8–10 hours, including 4 hours of welding for reinforced joints.

- Large Steel Arch Buildings: For spans exceeding 18m, allocate 3–4 workers and 12–16 hours to ensure precise alignment.

- Pre-Installation Preparation

- Foundation Readiness: Level and cure concrete footings (20cm thickness recommended) at least 7 days before delivery—this prevents delays for livestock buildings requiring fixed bases.

- Component Inventory: Cross-check beams, panels, and bolts against the packing list. Report discrepancies within 24 hours of receipt.

- Welding & Assembly

- Use J422 electrodes for G550 steel frames to maintain tensile strength (≥420MPa).

- Prioritize welding main column-to-baseplate joints first, followed by secondary purlin connections, ensuring ≤2mm deviation across 10m spans.

- Post-Installation Checks

- Verify door/window operation (3–5mm clearance tolerance) to prevent drafts in metal animal shelters.

- Apply silicone sealant along roof panel overlaps to enhance waterproofing—critical for poultry houses.

Pro Tip: Schedule installations during dry seasons to avoid moisture-related steel expansion issues. For customized livestock barns and shelters, request our 3D assembly guide with torque specifications for bolt tightening.

SteelPRO PEB’s shelters are engineered for hassle-free assembly, letting you focus on what matters—your animals’ comfort.

Tailored Solutions for Every Livestock Need

SteelPRO PEB delivers precision-engineered metal livestock shelters designed to meet diverse agricultural demands. Explore our specialized solutions:

- Small Monoslope Cattle Barn: Compact and storm-resistant, ideal for herds under 20 cattle.

- Pole Barn Stables: Spacious layouts with natural ventilation for equine health.

- Steel Structure Pig House: Hygienic, slatted-floor designs for efficient swine management.

- Steel Structure Cowshed: High-roof configurations (7m+) optimized for dairy workflows.

With 3 ISO 9001-certified production lines and 500+ annual installations, we guarantee durability backed by a 15-year anti-corrosion warranty. Our customization capabilities let you adapt every detail—from adjusting roof slopes for heavy snow loads to integrating automated feeding systems in pig houses.

Whether you need a modest metal animal shelter, a 30m-span steel arch shelter, or adaptable farm shelters, SteelPRO PEB combines innovation with practicality. Contact our engineering team to design a shelter that aligns with your livestock’s needs and your farm’s growth.