What Size Farm Equipment Shed Do You Need?

Not sure which farm equipment storage building size fits your operation? The right dimensions protect your tractors, tools, and investments—no wasted space or cramped aisles. Explore our most popular tractor equipment shed sizes below, matched to real-world farming needs.

| Size (L x W) | Fits Equipment |

| 30’ x 40’ | 2-3 mid-sized tractors + attachments (e.g., plows, seeders) or 1 combine + workshop space |

| 40’ x 60’ | 4-5 large tractors, 20+ pallets of feed/supplies, or 2 combines with aisle space |

| 50’ x 80’ | 6-8 tractors + implements, grain bins, or livestock bedding storage + equipment maintenance area |

| 60’ x 100’ | 10+ tractors, hay balers, and forage harvesters; ideal for multi-farm cooperatives |

| 40’ x 100’ | Long equipment (e.g., 4 cotton pickers or 6 hay wagons) + narrow-aisle access |

| 24’ x 36’ | 1-2 compact tractors, ATVs, and small implements; budget-friendly starter shed |

| 50’ x 50’ | 3-4 large tractors with front loaders + pallet racking for parts/tools |

| 60’ x 120’ | Bulk storage: 12+ tractors, combines, or 200+ round hay bales; expandable for future needs |

| 36’ x 48’ | 2 standard tractors + fertilizer spreaders + secure chemical storage room |

| 48’ x 72’ | Hybrid use: 3-4 tractors, workshop, and 40’x20’ covered area for drying/curing equipment |

Tips for Choosing Your Size:

✅ Think 5 years ahead – Will you add more equipment?

✅ Measure your largest gear (include attachment clearance!).

✅ Consider site slopes/drainage – Flat pads simplify installation.

✅ Local climate matters – Wider sheds handle snow drift better.

✅ Need a hand? Share your equipment list – we’ll match you to the perfect size.

What’s Included in Your Custom Farm Equipment Shed

| Category | Specifications | Details |

| Main Steel Frame | Columns, Beams, Trusses, Bracing System | ASTM A572 Grade 50 steel, hot-dip galvanized, 12-14 gauge thickness |

| Secondary Frame | Purlins, Girts, Tie Rods | 16-18 gauge steel, galvanized, spaced 4-5 ft apart |

| Roofing & Wall Systems | 26-gauge steel panels (Galvalume® or Galvanized), Insulation options | R-13 insulation optional, 40-year corrosion warranty |

| Structure Add-ons | Roll-up Doors, Ventilation Louvers, Gutters, Downspouts | Custom door sizes (up to 20’x16’), PVC or steel gutters |

| Customization Options | Size (up to 150’x300’), Color (20+ options), Door Types, Skylights | Lean-to extensions, partition walls, interior lighting |

| Building Usage | Equipment Storage, Livestock Shelter, Workshop, Hay Storage | Clear-span design, no interior columns |

| Structural Strength | Wind Load (130 mph), Snow Load (40 psf), Seismic Zone 4 compliant | Engineered for ASCE 7-16 standards, includes anchor bolt plans |

| Sustainability | 100% recyclable steel, Energy Star® reflective roof coatings | Reduced HVAC costs with insulation, rainwater harvesting compatible |

| Temperature Range | -40°F to 120°F (-40°C to 49°C) | Compatible with ventilation systems for climate control |

| Processing Service | CNC cutting, Pre-punched holes, Welded connections, On-site assembly support | Custom fabrication (2-4 weeks lead time), bolt-together kits available |

What We Do Not Provide for Your Farm Equipment Shed

While we offer high-quality, prefabricated steel farm equipment sheds with full structural customization, there are a few things we do not provide:

- Interior Finishing & Flooring – We supply the steel structure and main building components, but interior finishes such as flooring, drywall, and decorative paneling are not included. Customers typically arrange these based on their specific operational needs.

- Electrical & Plumbing Systems – We provide structural provisions for electrical and plumbing installations, such as pre-punched conduit access points, but wiring, outlets, lighting fixtures, and plumbing lines must be installed separately by a local contractor.

- Foundation Construction – While we provide anchor bolt plans for securing the structure, excavation, concrete pouring, and foundation work must be completed before installation.

- Agricultural Equipment & Storage Fixtures – Our farm sheds are designed to protect your machinery, but items such as tool racks, shelving units, fuel tanks, or storage bins are not included. These can be easily added to your shed based on your specific storage requirements.

- Building Permits & Approvals – Our structures are engineer-certified, and we provide detailed blueprints, but obtaining local building permits and regulatory approvals is the responsibility of the customer.

We focus on delivering strong, durable, and fully customizable steel farm sheds, giving you the flexibility to tailor interior layouts and additional features based on your unique needs.

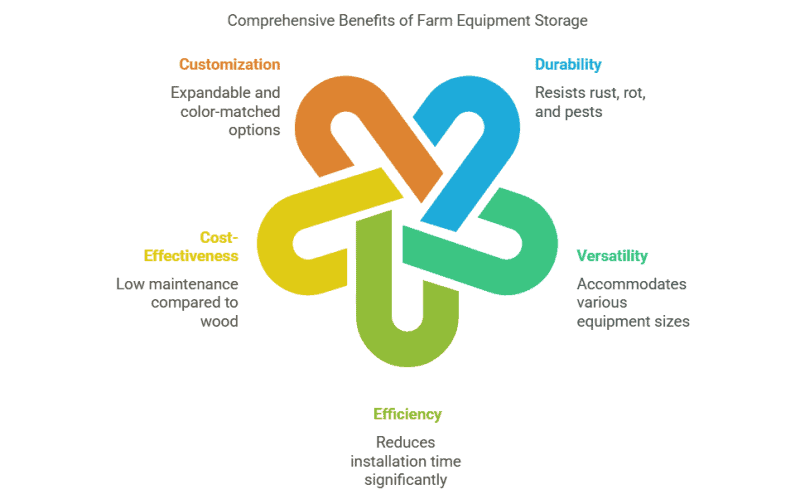

Why Choose Our Farm Equipment Storage Buildings?

1. Built to Last: Steel-Frame Durability for Farm Equipment Storage

- Galvanized steel columns and trusses (12-14 gauge) resist rust, rot, and pests that destroy wood/fabric sheds.

- Engineered for 130 mph winds and 40 psf snow loads—protects tractors, harvesters, and seasonal tools year-round.

- Our edge: Triple-layer anti-corrosion coatings applied during fabrication, exceeding industry standards.

2. Versatile Space: Designed for Multiple Farm Equipment Storage Needs

- Clear-span designs (up to 150’ wide) accommodate oversized tractors, balers, and implements without obstructions.

- Adjustable shelving and partition options keep small tools, seeds, or livestock supplies organized.

- Your tractor equipment shed won’t just store tools—it’ll protect them.

3. Faster Build, Lower Hassle: Prefab Efficiency You’ll Appreciate

- Pre-cut, pre-drilled components slash installation time by 60% vs. traditional builds.

- Bolt-together kits allow DIY assembly or hire local contractors—we provide detailed guides.

- Our precision: CNC-cut steel ensures perfect fitment, minimizing on-site adjustments.

4. Cost-Smart Protection: Low-Maintenance Farm Equipment Storage Shed

- Galvalume® roofing reflects UV rays to reduce indoor heat buildup, preserving battery-powered tools.

- No repainting or sealing required—unlike wood structures that decay in 5-7 years.

- Your farm equipment storage stays functional, not a maintenance chore.

5. Tailored to Your Farm: Flexible Farm Equipment Storage Buildings

- Expandable designs add lean-tos or bays later as your operation grows.

- Color-matched panels (20+ options) blend with barns or landscapes—no eyesores.

- We don’t just sell sheds; we build solutions that evolve with your farm.