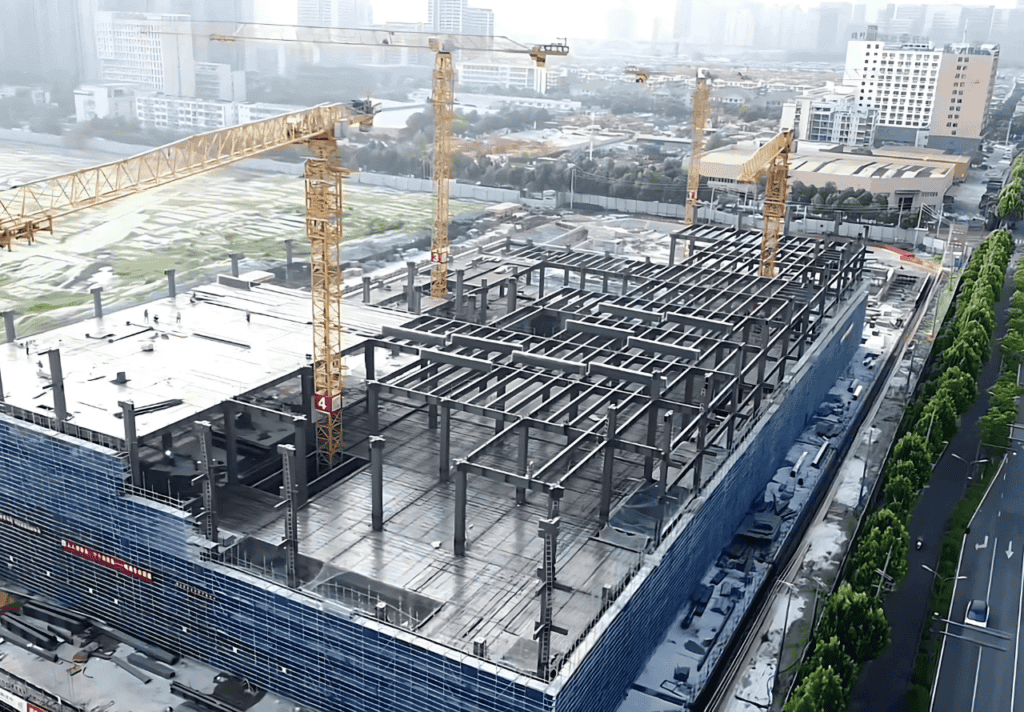

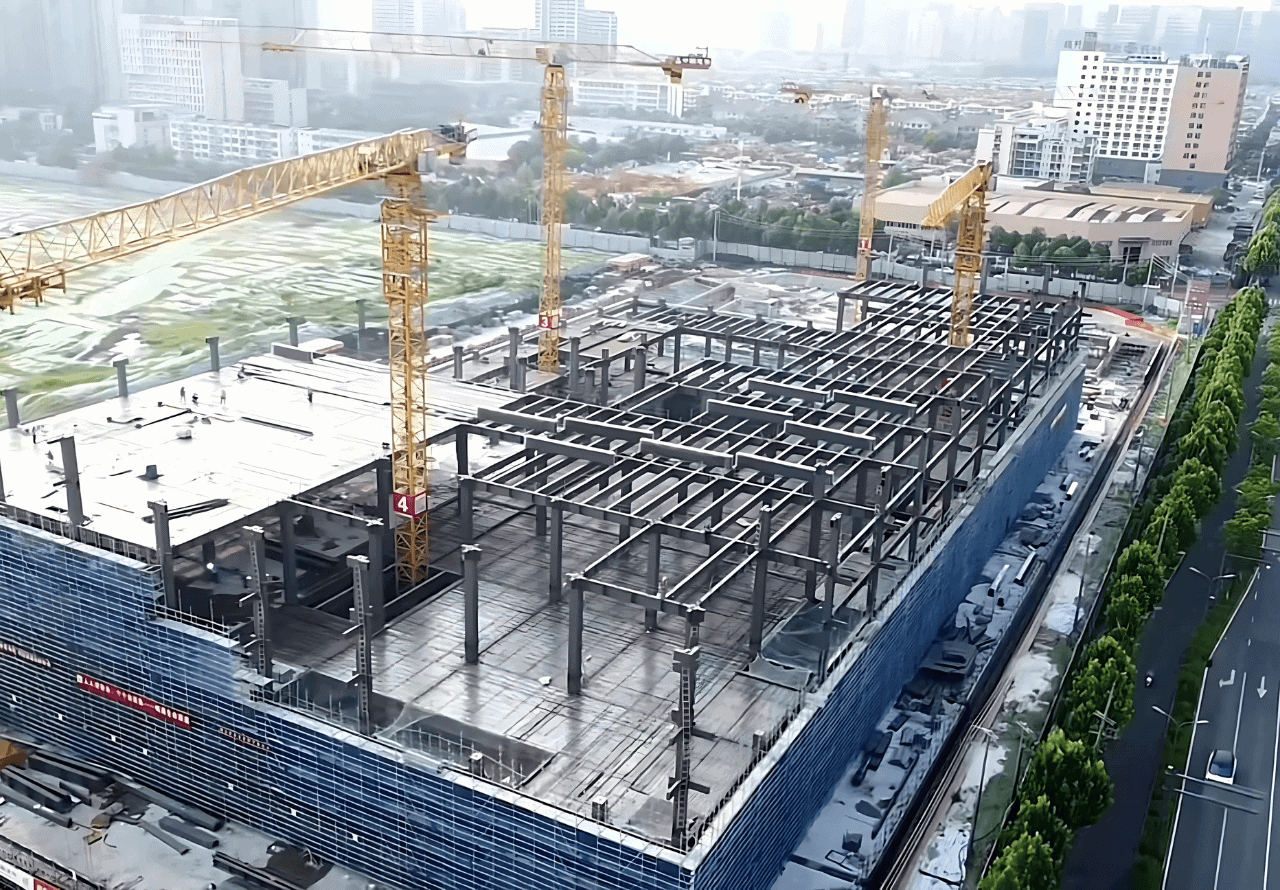

Why Choose Steel Structure When Building Supermarkets?

- Faster construction: Pre-fabricated parts mean quicker assembly, so you can start operations sooner.

- Cost efficiency: Steel uses fewer materials, cuts transport and labor costs, and reduces overall project time.

- More space: Without heavy support columns, you get more open space for better product displays and customer flow.

- Durability: Steel stands strong against weather, ensuring safety in storms or earthquakes, with low maintenance costs.

- Eco-friendly: Steel is recyclable, making it a greener option that reduces your carbon footprint.

- Flexibility: Need to expand? Steel structures can be easily modified to fit your growing business.

Our Services

We provide a comprehensive range of services to ensure your steel structure supermarket is efficient, functional, and tailored to your needs. Here’s how we help you build your ideal space:

- Custom design & color options: Tailored solutions for layout, appearance, functional zoning, and exterior color to perfectly match your brand.

- Energy-efficient design: We consider insulation, ventilation, and other factors to reduce operational costs and improve energy performance.

- Pre-installed fittings: We set embedded parts or connectors in the steel structure for easy and quick shelving installation.

- Mounting provisions: We leave holes or hooks on beams and columns for easy installation of suspended fixtures like lighting or signs.

- Fire protection: We apply fire-resistant coatings to ensure safety in high-traffic areas.

- Enhanced seismic performance: We design the structure to handle dynamic loads and improve vibration resistance.

- Open space design: The layout avoids obstructions to customer flow and sightlines, creating a more open shopping experience.

These services ensure a smooth, efficient build, and a safe, functional space for your supermarket!

You Will Get From Us

Here are our main and secondary structures, along with additional components. If you have other specific requirements, we will customize them for you while keeping within your budget!

| Component | Material | Common Specifications |

| Steel Columns | Q235 or Q345 steel | H-beam, sizes like 200×200 mm, 250×250 mm, 300×300 mm, height up to 12 meters or more, customized as needed. |

| Steel Beams | Q235 or Q345 steel | H-beam, sizes like 200×150 mm, 300×200 mm, 400×250 mm, span ranges from 10m to 50m depending on the design. |

| Roof System | Sandwich panel (EPS, rock wool, polyurethane) or single steel plate | Thickness: 50-150 mm, width: 1000 mm, length customized according to building size and span. |

| Wall System | Color steel plate, sandwich panel | Thickness: 50-100 mm, width: 1000 mm, length typically 6m-12m, customized based on wall area. |

| Bolts | Q235 steel | Anchor Bolts, High Strength Bolts, Normal Bolts |

| Steel Door and Window | Aluminum or steel | Door frame size: 1000×2000 mm, window frames customized as needed (single or double opening). |

| Shelf Embedded Parts | Q235 steel | Steel reinforcement bars or plates, diameter 10-20 mm, positioned on the ground or beams, location and quantity based on shelf layout. |

| Mounting Holes for Hanging Fixtures | Steel beams or columns | Hole diameter: 10-20 mm, number and location set according to the need for lighting, signage, etc. |

| Fire Protection Coatings | Fire-resistant coating | Coating thickness: 1-3 mm, depending on fire protection rating requirements. |

| Lighting/Skylights | PC board or tempered glass | Width: 600-1200 mm, length customized as per roof design, skylights generally cover 10%-20% of roof area. |

| Drainage System | Galvanized steel or PVC | Drain pipe diameter: 100-150 mm, length customized based on building design. |

| Exterior Wall Panels | Color steel plate or aluminum alloy | Thickness: 0.4-1.0 mm, width: 1000 mm, length customized as per design. |

| Load Capacity Customization | – | 1. Wind speed 2. Rain load 3. Snow load 4. Earthquake resistance grade (if applicable), etc. |

Shipping and Packaging

To ensure your steel structure supermarket arrives safely, we offer efficient and reliable shipping and packaging solutions:

- Container Shipping:

We use 40′ HC (High Cube) or 40′ STD (Standard) containers, depending on the size of the components. - Packaging:

- Steel parts are treated with anti-rust oil or film to prevent corrosion during transport.

- Small parts like bolts and fittings are packed in wooden boxes or plastic bags to keep them safe.

- Shipping Method:

We mainly use sea and land transport, with faster shipping options. - Loading and Unloading:

Heavy components are lifted using cranes to ensure safe and efficient handling. - Customization:

We offer tailored packaging and shipping options to fit your project needs.

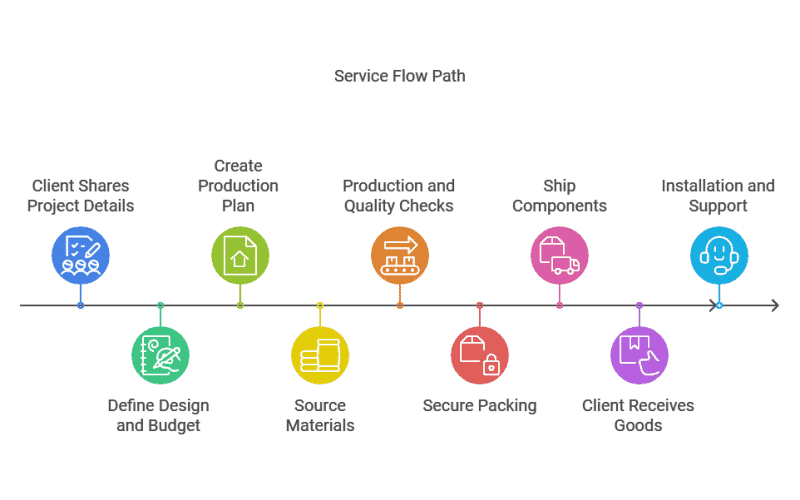

Our One-Stop Service Flow | Steel Structure Manufacturer

We know that running a supermarket is all about efficiency, durability, and creating the perfect shopping experience—and that’s where our steel structures shine. With top-grade materials and cutting-edge fabrication, we craft strong, precise components that are tailored to fit wide-open layouts, easy shelving setups, and seamless integration of lighting and signage.

Every detail is carefully refined and quality-checked to give you a structure that’s not just built to last but built to help your business thrive. From supporting smooth operations to enhancing customer flow, our steel structures are designed to meet the unique demands of your supermarket and drive your success!