Best Shipping Container Restaurant Sizes & Layouts for Different Uses

Choosing the right shipping container restaurant size and layout can make all the difference! Whether it’s a cozy café or a full-scale kitchen, we’ve got flexible options to match your vision. Here are recommended sizes and layout suggestions for different types of shipping container restaurants, ensuring optimal space utilization and efficiency:

| Type | Recommended Size | Layout Suggestions |

| Fast Food Takeout | 20ft, 30ft | Open kitchen facing the order window, limited storage, compact prep area. Ideal for high-speed service. |

| Drive-Thru Restaurant | 40ft, 2x20ft | Dual service windows for ordering and pickup, streamlined kitchen flow, exterior menu boards. |

| Pop-Up Restaurant | 20ft, 30ft | Modular design with foldable counters, a compact kitchen, and flexible seating. Easy to relocate. |

| Café & Coffee Shop | 20ft, 30ft, 40ft | Front-facing service counter, optional walk-in space, drive-thru window, seating inside or outside. |

| Food Court Stall | 10ft, 20ft | Minimalist layout with a service window, essential kitchen appliances, and efficient storage. |

| Outdoor Bar or Brewery | 20ft, 40ft | Bar counter with roll-up doors, refrigeration space, draft beer system, and seating integration. |

| Fine Dining Restaurant | 40ft, Multi-Unit | Expanded kitchen, enclosed dining area, HVAC system, high-end finishes, and ambiance-focused lighting. |

| Catering & Event Kitchen | 40ft, Multi-Unit | Large prep space, industrial kitchen equipment, ample refrigeration, and easy access for loading. |

| Ghost Kitchen | 40ft, Multi-Unit | Optimized kitchen layout with dedicated cooking, prep, and packaging areas, no dine-in space. |

| Beachfront or Resort Restaurant | 40ft, Multi-Unit | Open-air seating, weatherproof finishes, ventilation for coastal conditions, foldable walls/windows. |

What’s Included in Your Shipping Container Restaurant?

Every shipping container restaurant comes with essential features designed for durability, efficiency, and compliance. Plus, we offer a range of customizable options to match your business needs—whether you’re opening a fast food takeout, café, or full-scale dining space. Check out the key specifications below to see what’s included and what you can customize!

| Specification | Details & Options |

| Size | 10ft, 20ft, 30ft, 40ft, High Cube available; Custom dimensions upon request |

| Stacking & Combination | Single-unit, multi-level stacking, modular configurations, expandable units |

| Openings & Sizes | Pre-cut doors, windows, service hatches, and ventilation openings; Custom placement based on kitchen flow & customer access |

| Reinforcement Method | Steel beam reinforcements for cut sections, internal frame support, load-bearing reinforcements for rooftop decks & signage |

| Wall & Roof Materials | Insulation: Spray foam, rock wool, PU panels; Finishes: Corrugated steel, interior cladding (wood, aluminum, stainless steel) |

| Waterproofing | Weld seam sealing, exterior waterproof coatings, protective membranes, sloped roof drainage system |

| Door Types | Roller shutter, hinged steel doors, folding glass doors, automatic sliding doors, customized service hatches |

| Window Styles | Fixed, sliding, floor-to-ceiling windows, serving windows, folding or pass-through windows (optional security bars) |

| Skylight Design | Fixed or operable skylights, reinforced glass, rainproof sealing, manual or motorized opening |

| Design Load | Roof live load: Snow load, foot traffic (if rooftop seating); Stacking load: Multi-level capacity with reinforced steel beams |

| Transport Load | Crane lifting, forklift pockets, shock-resistant base, road transport compliance |

| Certification Requirements | CSC safety certification (for mobility), local building code compliance (fire, seismic, health regulations, ADA accessibility) |

| Rust Protection | Sandblasting, epoxy coating, galvanized treatment, marine-grade paint for coastal areas |

| Expected Lifespan | 10-30 years, depending on modification level and corrosion protection |

| Transport Adaptability | Retained corner castings for lifting, weight limitations for road transport, integrated twist-locks for stacking |

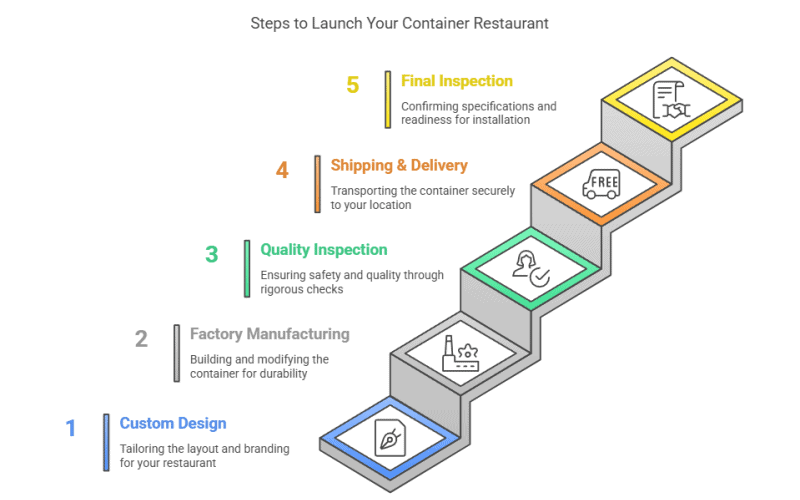

Our Shipping Container Restaurant Production Process

Bringing your storage container restaurant to life is a smooth and efficient process with us! From design to delivery, we ensure your restaurant shipping container meets your exact needs with quality craftsmanship and fast turnaround times.

Step 1: Custom Design & Planning

Every great cargo container restaurant starts with a solid plan! Our team works closely with you to create a tailored design, incorporating:

- Optimal layouts for your kitchen, service area, and customer space.

- Pre-cut openings for doors, windows, and ventilation to fit your operations.

- Branding elements such as exterior finishes, signage placements, and custom coatings.

We also help ensure your shipping container kitchen meets local regulations, making it easier to pass inspections and approvals.

Step 2: Factory Manufacturing & Modifications

Once the design is finalized, we begin fabrication using new, one-trip containers for maximum strength and durability. Key modifications include:

- Structural reinforcements to maintain integrity after window and door installations.

- Pre-installed utility routes for water, electricity, and ventilation.

- High-quality insulation and weatherproof coatings to ensure long-term use.

Step 3: Quality Inspection & Safety Checks

Before shipping, every restaurant shipping container undergoes strict quality control, including:

- Structural integrity checks to confirm reinforcements are secure.

- Waterproofing and rust-proofing tests to ensure longevity.

- Final inspections to verify all modifications meet safety and quality standards.

Step 4: Shipping & Delivery

Once your cargo container restaurant passes inspections, we arrange safe and efficient transport. Our team ensures:

- Secure loading and handling to prevent damage in transit.

- Flexible shipping options for domestic and international deliveries.

- Support for unloading preparation to help you get ready for installation.

Step 5: Final Inspection & Installation on Your Site

Upon arrival, you’ll inspect your storage container restaurant to confirm it meets specifications. While we don’t handle on-site installation, we provide:

- Guidance on setup requirements for a smooth installation process.

- Compliance assistance to help you quickly pass local approvals.

- After-sales support for any questions regarding modifications or setup.

With our efficient process and expert team, launching your shipping container restaurant is faster, easier, and more cost-effective. Let’s get started on your project today!

Build a Shipping Container Restaurant That Stands Out

We believe every container restaurant should be as unique as the business it serves. That’s why flexible customization is at the core of what we do. From the initial concept to final production, we work closely with you, ensuring that every detail aligns with your vision, operational needs, and branding.

Our expertise goes beyond construction—we help you optimize layouts for smooth kitchen workflow, enhance customer accessibility, and incorporate smart space-saving solutions. Need extra storage? A rooftop seating area? A seamless integration with existing utilities? We provide the structural modifications and reinforcements needed to make it happen.

Through multiple touchpoints during the manufacturing process, we keep you involved every step of the way. From refining designs to pre-cut openings and reinforcements, we ensure your shipping container kitchen is built exactly to your specifications. With precision engineering, durable materials, and a client-focused approach, we deliver a final product that meets your expectations—on time and ready for success.