Agricultural building types

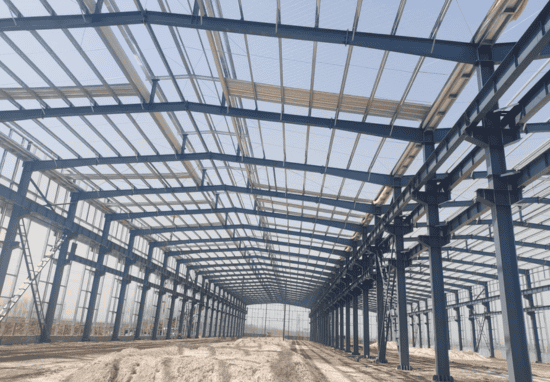

Our steel agricultural buildings are designed to meet the full range of industry needs, from animal breeding and crop storage to production and processing. We offer four main product types:

Animal breeding buildings

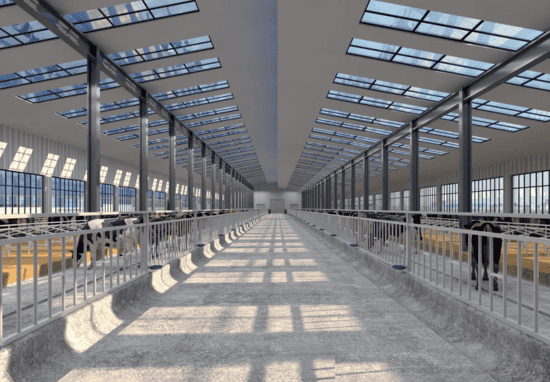

- Animal houses (cows, sheep, pigs): Our animal houses are designed to suit various types of animal breeding, providing ample space, good ventilation and easy-to-clean structures. The steel structure ensures durability during long-term use and protects livestock from extreme weather.

- Poultry houses (chickens, ducks, turkeys): Flexible design, good air permeability, can effectively control humidity and temperature, provide a comfortable environment, and improve poultry productivity.

- Stables, milking parlors, hatcheries, veterinary isolation rooms: For special needs, we provide stables, milking parlors and dedicated veterinary isolation rooms to ensure the health and production efficiency of animals.

Crop storage buildings

- Granaries, hay sheds, silage towers, constant temperature fruit and vegetable warehouses: The design ensures that the crop storage environment is dry and the temperature is constant, reducing moisture and mildew, especially suitable for storing grains, hay, fruits and vegetables, etc.

- Drying room, root crop cellar: suitable for drying and storing grain and root crops, optimizing space layout to ensure that crops can be preserved under optimal conditions.

Production and processing buildings

- Feed processing workshop, dairy processing room, meat cold storage: suitable for feed processing, dairy processing and meat storage on the farm, our steel structure buildings can provide a stable temperature control environment to ensure food safety and quality.

- Agricultural machinery repair workshop, packaging and sorting area: specially designed for farm equipment maintenance and product processing, with a stable structure and reasonable design, which can improve production efficiency.

Auxiliary facilities buildings

- Greenhouse, seedling workshop, biogas tank roof: auxiliary facilities that meet different agricultural production needs and provide a better growth environment.

- Water tower/pump room, tool room, employee rest area: provide necessary infrastructure for farm staff and equipment to increase work efficiency and comfort.

Our combination design scheme

We provide a variety of combination design schemes to achieve flexible integration of functional areas according to customer needs:

Cross-type functional integration

For example, we can install solar panels on the roof of the livestock house, combined with a rainwater collection system, to reduce energy consumption and utilize natural resources to provide customers with sustainable building solutions. This integrated design is not only energy-saving and environmentally friendly, but also reduces long-term operating costs.

Modular splicing design

Our buildings adopt modular splicing methods, which can closely connect functional areas such as warehouses, office areas, and agricultural machinery repair stations according to needs, optimize space use and improve farm operation efficiency. Modular design not only saves time, but also facilitates future expansion or adjustment.

Independent partition design

For customers who need functional separation, we provide independent partition solutions. Through fireproof partitions and independent ventilation systems, such as separating the breeding area from the processing workshop, ensure the safety, hygiene and production efficiency between different functional areas. This design can effectively avoid cross contamination and improve production safety.

Environmental performance

Environmental protection and sustainability are one of the core values of our products. We are committed to providing green building solutions that meet the needs of modern agriculture:

100% recyclable steel: The steel used in our buildings complies with ISO 14001 standards, is fully recyclable and meets environmental requirements.

Integrated environmental protection system: We provide optional integrated environmental protection solutions, including solar panel brackets and rainwater collection tank pre-installed interfaces.

Energy-saving design: All building designs focus on improving energy efficiency, using high-quality insulation materials and sealing technology to reduce energy consumption and ensure the comfort and stability of the farm environment.

Farm Buildings Product Specifications

| Category | Details |

| Product Types | Agricultural Warehouses, Livestock Barns, Machinery Sheds, Greenhouses, etc. |

| Standard Sizes | – Width: 12m – 30m- Length: 24m – 60m- Height: 4m – 8m |

| Custom Sizes | Non-standard sizes available to meet specific site requirements |

| Main Materials | – Steel: ASTM A572 Grade 50 galvanized steel, anti-corrosion- Coating: PVDF or polyester coating for enhanced durability |

| Structural Design | – Modular design for easy transportation and installation- High-strength steel beams (up to 50 ksi yield strength) for stability |

| Roof & Walls | Corrugated steel panels (26-29 gauge), lightweight and durable, available in multiple colors (e.g., red, blue, green, white) |

| Wind Resistance | Can withstand wind speeds of up to 150 mph (67 m/s) |

| Seismic Resistance | Complies with IBC (International Building Code) seismic standards |

| Fire Rating | Meets Class A fire resistance standards |

| Lifespan | Over 50 years with proper maintenance |

| Basic Features | – Ventilation system: Ridge vents and sidewall curtains- Natural lighting: Translucent panels (up to 10% roof coverage)- Insulation: R-15 to R-30 insulation options for temperature control |

| Optional Accessories | – Doors & Windows: Roll-up doors, sliding doors, or double-leaf doors- Drainage system: Gutter and downspout systems- Lighting: Energy-efficient LED lighting (100-200 lux)- Automation: Automated feeding systems, climate control, etc. |

| Eco-Friendly Features | – 100% recyclable steel- Eco-friendly coatings (low VOC)- Energy-efficient design (reduced carbon footprint) |

| Maintenance | – Regular inspections of joints and drainage systems (annually)- Full inspection every 5 years– Reapply anti-corrosion coatings every 10-15 years |

Notes

- The above specifications are based on industry standards and can be customized to meet specific requirements.

- All products comply with international building codes (IBC) and undergo rigorous quality inspections.

- For detailed technical drawings or custom solutions, please contact us for more information.

Service and Support

We are committed to providing high-quality products and comprehensive support services to every customer to ensure that your agricultural building project proceeds smoothly and achieves the best results. We provide the following services and support:

1. Professional consultation and customized design

Requirement analysis: Our team of experts will provide detailed consultation based on your specific needs (such as site, function, budget, etc.) to help you choose the most suitable building type and configuration.

Customized design: According to your needs and site conditions, we provide tailor-made building design solutions to ensure that every detail meets your expectations.

2. Efficient delivery and installation support

Fast delivery: With our efficient production and logistics system, steel structure components will be delivered to your project site on time to ensure that the project can be started quickly.

Professional installation service: We provide construction technical guidance to ensure that the construction process meets quality standards and safety regulations.

3. Quality assurance and after-sales service

Long-term warranty: All steel structure buildings provide up to 50 years of structural quality guarantee and 25 years of coating durability guarantee to ensure the long-term stability of the product.

After-sales support: Our after-sales team is always available to provide you with technical support and maintenance services. If any problems arise, you can contact the after-sales service center and we will respond quickly and provide solutions.

4. Maintenance and renovation

Preventive maintenance: We provide regular maintenance services to check the structural integrity and coating condition to extend the service life of the building.

Upgrade and renovation: As your business needs change, we also provide building expansion, renovation and upgrade services to help you respond to changes in a timely manner.

FAQs

Does the silage tower have higher anti-corrosion requirements?

Yes, silage towers usually require stronger anti-corrosion performance because they are in a silage fermentation environment with more moisture and acidic substances. We use double-layer galvanized steel + acid-resistant coating to ensure that the silage tower still maintains good corrosion resistance in long-term use.

How to prevent the floor of the milking parlor from slipping?

In order to ensure the safety of the milking parlor, we provide optional anti-slip steel grid floors. In addition, the ground drainage slope can also be customized according to needs to ensure the safety of dairy cows and staff.

Can a ventilation system be customized for a biogas tank?

We support the customization of a forced exhaust system for a biogas tank to ensure air circulation inside the biogas tank and prevent the accumulation of harmful gases. In addition, we have reserved interfaces for equipment installation to facilitate the rapid access of later equipment.