Advantages of a Steel Structure Cowshed

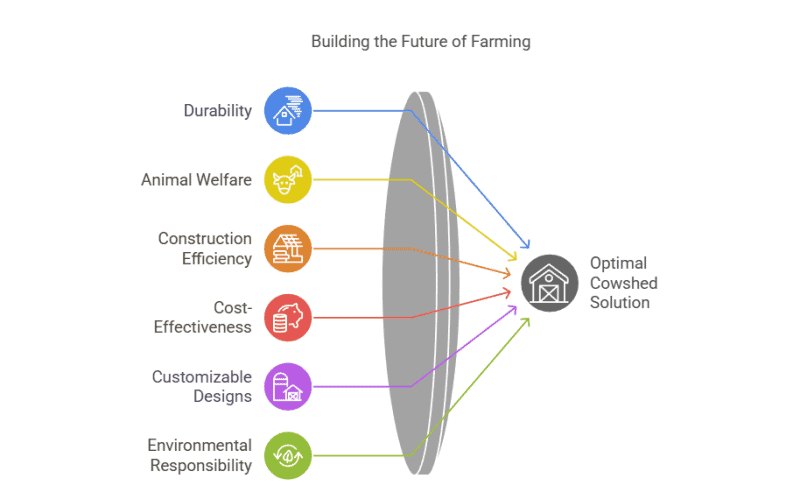

Choosing a Steel Structure Cowshed means benefiting from a more durable, cost-effective, and efficient solution. Here’s why steel is the best choice:

- Unmatched Durability: Built to endure! Designed with robust materials to withstand harsh weather and provide 30-50+ years of reliable service – that’s more than timber.

- Optimized Animal Welfare: Promote a healthy herd! Open designs and optional automated ridge vents reduce humidity by up to 30%, minimizing respiratory issues and maximizing milk yields.

- Fast & Efficient Construction: Get up and running sooner! Pre-fabricated components and a streamlined design process cut construction time drastically.

- Low Lifetime Costs: Minimize expenses! Rot-proof, pest-resistant materials significantly reduce annual maintenance costs, freeing up your resources for growth.

- Fully Customizable Designs: Create your ideal layout! Clear spans accommodate free-stall, tie-stall, and robotic milking setups, maximizing space and workflow.

- Environmentally Responsible: Support sustainability! Steel’s recyclability reduces your farm’s environmental footprint, aligning with responsible farming practices. Benefit from our hot-dip galvanizing process that is environmentally friendly.

Buyer’s Guide – What to Consider Before Purchasing a Cowshed

Building a successful cowshed requires careful planning. Here’s what to consider:

Location and Site Selection

Prioritize well-drained land with at least a 2-3% slope for effective runoff. Locate the cowshed 500+ meters from potential pollution sources to minimize disease risks. Aim for east-west orientation to optimize sunlight exposure and minimize heat stress.

Design Considerations

Maximize cow comfort! Aim for a 4-meter eave height to enhance natural ventilation. Consider adjustable side curtains for 30% humidity reduction. Insulated metal panels (R-value of 5.0+) drastically cut heating/cooling costs.

Capacity and Animal Accommodation

Ensure adequate space. Allocate 8-12 square meters per cow for free-range and 4-6 square meters for confined stalls. Factor in breed variations – Holstein cattle need more space! Aisle widths of at least 3 meters are crucial for smooth equipment operation.

Functional Zoning

Optimize workflow and hygiene:

- Resting Areas: Prioritize cow comfort with rubber mats (reduces stress by 20%)

- Feeding Zones: Easy-access troughs and feeding lines minimize feed waste.

- Milking Stations: Separate, well-lit sections streamline dairy operations.

- Manure Management: Automated scraper systems cleaned twice daily can minimize odors.

- Quarantine Zones: Allocate at least 5% of total area for sick cow isolation.

Stuck on zoning? Contact us with your questions now! Get a customized steel structure layout proposal tailored for efficiency and herd comfort within just 48 hours!

Steel Structure Cowshed: Product Specifications

Here’s what makes up our steel structure cowsheds—and don’t forget, we can customize everything to fit your farm perfectly!

| Specification | Details |

| Type | Free Stall Barn, Tie Stall Barn, Loose Housing System (Customizable) |

| Main Steel Frame | Q345B Steel, Hot-Dip Galvanized, Welded/Bolted Connections, Designed to local codes |

| Secondary Frame | C-Purlins, Z-Purlins, Angle Bracing, Hot-Dip Galvanized or Painted |

| Roofing System | Material: Insulated Metal Panels (IMP), Single-Skin Steel with Insulation; Colors: Customizable; Includes Gutters & Downspouts (Galvanized Steel or PVC Options) |

| Wall System | Material: Insulated Metal Panels (IMP), Single-Skin Steel with Insulation; Colors & Profiles: Customizable. |

| Door | Sliding Doors, Rolling Doors, Sectional Doors, Steel or Aluminum Construction |

| Windows | Steel Frame Windows, Aluminum Frame Windows, Louvered Windows for Ventilation |

| Customization Options | Ventilation Systems, Lighting, Gutter Systems, Manure Management Systems, etc. |

| Construction Time | Typically 4-8 weeks, depending on size and complexity. Expedited options available! |

Let’s Build Your Ideal Steel Cowshed!

Whether you need a simple open cattle shelter or a fully insulated dairy barn, our Steel Structure Cowsheds are designed to provide durability, comfort, and efficiency. Contact us today to get a customized solution that fits your farm’s needs!