What is a Steel Structure Poultry Building?

Steel structure poultry buildings, also called pre-engineered metal poultry houses or galvanized steel coops, feature prefabricated frames with corrugated metal cladding. Key advantages include 25+ year durability, fire/termite resistance, and minimal upkeep. Unlike wooden sheds, they prevent rot, withstand heavy snow loads (up to 50 psf), and allow seamless ventilation integration via pre-punched panel holes.

Key Differences & Uses: Steel poultry buildings require no pest treatments or seasonal resealing, reduce disease risks with non-porous surfaces, and enable 3x faster assembly than wood. While primarily used for commercial operations (1,000+ birds) and climate-controlled breeding facilities (65°F-75°F), their modular designs also suit small-scale backyard flocks, supporting manual or automated feeding systems in home setups.

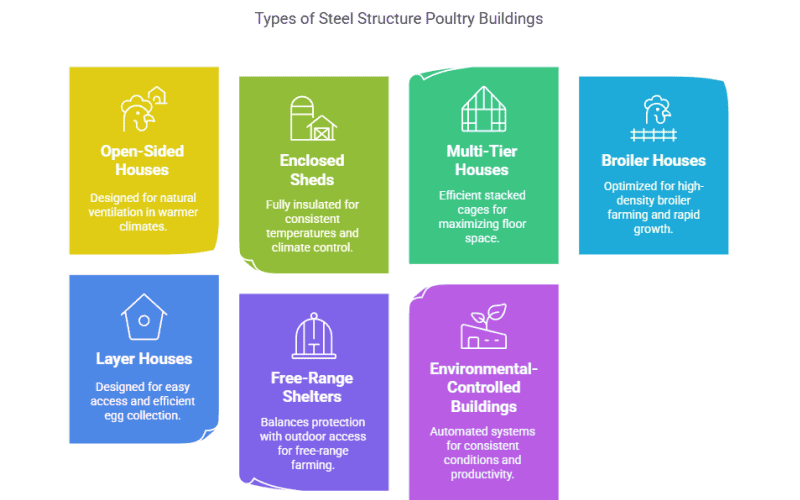

Types of Steel Structure Poultry Building

Building the right poultry house starts with choosing the right type for your operation. We offer a wide variety of designs to fit your needs, all built with the strength and durability of steel:

Open-Sided Poultry Houses: Designed for natural ventilation, ideal for warmer climates where airflow is key. Featuring Clear Span Rigid Frame Structures to maximize unobstructed airflow and promote bird health.

Enclosed Poultry Sheds: Fully enclosed and insulated for consistent temperatures, protecting your flocks from harsh weather and maximizing climate control. Built with Modular Steel Framing for rapid construction and easy integration of climate control systems.

Multi-Tier Poultry Houses: Maximize your floor space with efficient stacked cages or deep-litter systems, perfect for large-scale operations. Engineered with robust Steel Truss Systems to handle the multi-level design and heavy loads with confidence.

Broiler Chicken Houses: Specifically designed for high-density broiler farming, optimizing ventilation, feeding systems, and waste management for rapid growth cycles. Constructed with either Rigid Frame or Hybrid Steel-Concrete Systems, customized to your specific needs and budget.

Layer Chicken Houses: Streamline your egg production with layouts designed for easy access and efficient egg collection. Our steel structure chicken house designs benefit from Clear Span Rigid Frames, creating an open, accessible environment for optimal egg gathering and equipment management.

Free-Range Poultry Shelters: Provide a safe haven while allowing outdoor access, balancing protection with the benefits of free-range farming. Often utilizing Post and Beam Steel structures or smaller Rigid Frame designs for cost-effective and durable shelter.

Environmental-Controlled Poultry Buildings: Equipped with automated climate control, including ventilation, heating, and cooling systems, ensuring consistent conditions for poultry health and productivity. Rely on Hybrid Steel-Concrete Systems to deliver exceptional insulation and temperature stability, maximizing energy efficiency.

We offer a wide variety of steel structure poultry buildings to fit your needs. From space-optimizing multi-tier houses to climate-controlled enclosed sheds and naturally ventilated open-sided designs, we’ve got you covered!

How to Choose the Right Steel Structure Poultry Building for Your Needs

Selecting the right steel structure poultry building depends on your farming scale, bird type, and operational needs. As an experienced steel structure manufacturer, we help customers design the most suitable poultry house by considering key factors like building height, span, functional requirements, and climate conditions. We aim to craft solutions that balance cost, efficiency, and long-term performance.

1. Choosing the Right Height

- 2.5m – 3m (Standard Height): Ideal for broiler farms and small to medium-scale layer houses where space efficiency is a priority. This height allows for easy feeding system installation and proper ventilation control.

- 3.5m – 4.5m (Medium Height): Best for large-scale poultry houses requiring mechanized ventilation, automated feeding systems, and manure removal equipment. This height also improves airflow and disease prevention, and you can more easily intgrate cooling pads, exhaust fans.

- 5m and Above (High-Rise Poultry Buildings): Suitable for multi-tier cage systems in intensive farms. A higher structure accommodates stacked cages, optimizing bird capacity per square meter while maintaining airflow and lighting efficiency. You can utilize a tunnel ventilation for your farms.

2. Selecting the Right Building Size (Span & Length)

- 8m – 12m Span (Compact Poultry Houses): Works well for free-range farms and smaller poultry operations, balancing cost and efficiency while providing ample protection from harsh weather.

- 12m – 16m Span (Standard Poultry Sheds): Common for commercial broiler and layer farms, allowing room for automated feeding and drinking systems while keeping construction costs controlled.

- 16m – 20m Span (Large-Scale Poultry Facilities): Designed for intensive farming with high-density cage systems, maximizing space for mechanized egg collection, manure removal, and climate control.

The length of the poultry house depends on your capacity needs, typically ranging from 50m to 150m, ensuring efficient workflow, feeding system placement, and ventilation management.

3. Considering Climate & Environmental Factors

Adapting your steel structure to the local climate is critical for bird health and performance:

- Hot & Humid Regions: Open-sided structures with natural ventilation, potentially combined with an evaporative cooling system, help maintain a stable environment. Proper steel coating such as using galvanized coating is important

- Cold Climates: Fully enclosed, insulated poultry houses with heating systems are best for temperature control and reducing energy costs. You can also consider sandwich panels for construction.

- Windy or Coastal Areas: Buildings reinforced with stronger bracing systems and corrosion-resistant materials for enhanced durability against extreme weather.

4. Customizing Functional Areas

Planning for these features early on will improve the long-term efficiency of your operation:

- Automated Feeding & Drinking Systems: Ensure the building design allows for easy installation and maintenance of your preferred system for efficiency and labor savings.

- Lighting & Ventilation: Strategic placement of side windows, exhaust fans, and roof vents is essential for flock health and minimizing energy costs.

- Operation Room & Aisles: Dedicated spaces for farm management, equipment storage, and worker access improve overall operational efficiency.

Let’s Build the Right Poultry House for You!

Every farm has unique requirements, and we’re here to help you design the perfect steel structure poultry building. Whether you need a compact free-range shelter or a large-scale automated facility, our custom-built poultry houses ensure durability, efficiency, and long-term performance. Let’s discuss your project and create a solution tailored to your needs! We’re excited to partner with you on this journey!

What We Provide For Your Steel Structure Poultry Building

| Component | Parameter Examples | Material Type Examples | Material Shape Examples |

| Foundation (Anchor Bolts) | Size (M20x300mm), Tensile Strength (8.8 Grade), Corrosion Protection (Hot-Dip Galvanized) | High-Strength Alloy Steel | Threaded Rod |

| Main Steel Frame | Steel Grade (Q345B), Section Shape (I-Beam, Box Section), Connection Type (Welded/Bolted) | Q345B Structural Steel | I-Beam, Box Section |

| Secondary Steel Structure (Girts & Purlins) | Thickness (1.5-3mm), Coating (Hot-Dip Galvanized), Spacing (Design Specific) | Hot-Dip Galvanized Steel | C-Channel, Z-Purlin |

| Roof & Wall Panels | Panel Type (Sandwich), Thickness (0.4-0.7mm), Coating (PVDF) | Galvanized/Aluzinc Steel Sheet, PU Sandwich Panel | Corrugated Sheet, Flat Sheet |

| Doors & Windows | Size (Custom), Sealing Grade (IP54), Material (Steel) | Cold-Rolled Steel Sheet | Rectangular Frame, with Seals |

| Accessories (Fasteners, Trim, etc.) | Size (M12-M20), Corrosion Protection (Galvanized) | Carbon Steel/Stainless Steel | Bolts, Angle Brackets, U-Channels |

| Operation Room & Aisle Supports | Support Structure (Square Tube, Angle Steel), Load Capacity (Design Specific) | Q235B Steel | Square Tube, Angle Steel |

| House Span/Length/Height | Span (12-36m), Length (Unlimited), Height (3-8m) | Based on Frame Design | Customized Steel Structure |

| Feeding & Drinking System Supports | Load Capacity (Design Specific), Corrosion Resistance (Hot-Dip Galvanized) | Hot-Dip Galvanized Steel | Channel Steel, Brackets |

| Temperature Control & Epidemic Prevention | Insulation Layer (Rockwool/PU), Sealing Design | Sandwich Panels, Sealant | Sheet Material, Sealant Strips |

| Lighting & Ventilation Supports | Installation Point Spacing, Load Capacity (Fixture/Fan Weight) | Q235B Steel | Angle Steel, Hanger Rods |

To ensure clarity and focus on our steel structure expertise, please note the following services that are typically not included in our scope:

Foundation Construction: While we provide the critical anchor bolts and precise layouts for their placement, the actual concrete foundation work is generally handled separately.

Utility Installations (Plumbing/Electrical): Our focus is on the steel structure itself; therefore, plumbing and electrical wiring are typically installed by specialized contractors.

Internal Farming Equipment Systems: Feeding, watering, climate control (beyond structural supports), and egg collection systems are usually sourced and installed by specialized vendors in the poultry industry.

Interested in a Custom Steel Structure Poultry Building?

To provide you with a detailed, tailored solution, we’ll need a little information about your operation and vision! Please consider the following:

- Building Dimensions: Length, width, height (including eave height), and roof pitch will determine the overall scale and interior space.

- Operational Needs: What type of poultry will you be raising (broilers, layers, free-range, etc.)? What’s your target bird capacity? This influences the interior layout and equipment needs.

- Functional Requirements: Describe any specialized equipment or features you plan to incorporate (automated feeding/watering, egg collection, manure removal systems).

- Climate and Location: Your geographic location is crucial for determining wind and snow load requirements. Also, understanding your climate will help us recommend the best insulation and ventilation strategies.

- Design Loads: Understanding your location helps us to customize designs to provide wind resistance, snow loads and rain resistance.

- Insulation Needs: Are you planning on a naturally ventilated open-sided or enclosed poultry house with insulation materials such as clip-on insulation layers or sandwich panels?

- Material Preference: Let us know your coating and thickness preference.

Providing these details will allow our team to craft a steel structure poultry building that perfectly meets your specific requirements, ensuring the health and productivity of your flock for years to come! We are excited to hear from you and bring your vision to life.

We are happy to collaborate with your chosen contractors and provide technical specifications to ensure seamless integration with our steel structure. We can also offer recommendations for reputable vendors in these areas. Our priority is to deliver an outstanding steel structure that forms the robust core of your poultry operation.