Steel is widely used in modern buildings for its strength and durability, but it can create challenges in how space is used and how different elements fit together. One area where this is noticeable is with staircases. They must be safe, functional, and also fit into the design of the building. Steel staircases are the ideal solution. They are strong, flexible in design, and built to last. Steel staircases improve both the functionality and look of a space. This article will guide you through the essential aspects of steel staircases, including their advantages, structural components, design options, fabrication and installation processes, and key safety requirements, helping you make an informed decision for your project.

Table of Contents

What is a Steel Staircase?

A steel staircase is a stair system primarily made of steel, commonly used in industrial plants, commercial buildings, warehouses, gymnasiums, and other steel structures. It consists of steel beams, columns, plates, and other components, connected through welding or bolting to form a stable structure. The design and manufacturing of steel staircases can be customized to meet the specific needs of a building, ensuring seamless integration with its overall style and functionality.

Advantages of Steel Staircases

- High Strength and Durability: Steel has exceptional strength and load-bearing capacity, making it ideal for industrial and high-traffic environments.

- Design Flexibility: Steel staircases can be customized to fit spatial and functional requirements, offering options like straight, spiral, and curved designs.

- Quick Installation: Prefabricated components allow for efficient on-site assembly, reducing construction time.

- Superior Fire Resistance: Compared to wooden staircases, steel staircases offer better fire resistance, complying with building safety standards.

- Low Maintenance Costs: Steel, when treated with anti-corrosion coatings, has a long lifespan and requires minimal upkeep.

- Eco-Friendly and Sustainable: Steel is recyclable, aligning with green building principles.

Basic Components of a Steel Staircase

A steel staircase primarily consists of the following parts:

- Stringers: The main structural elements supporting the staircase, typically made of I-beams or channel steel.

- Treads: The horizontal steps where users walk, often made of steel plates or grating with anti-slip surfaces.

- Risers: The vertical parts connecting the treads, though some designs may omit risers for an open appearance.

- Handrails and Guardrails: Safety features usually made of steel pipes or frames.

- Balusters/Spindles: Vertical posts that support the handrail and prevent falls.

- Landings: Platforms connecting different flight segments or changing directions.

- Support Beams: Structural elements that anchor the staircase to the building.

- Connections: Bolts, welds, or other fasteners securing the staircase to the building’s main structure.

Types of Steel Staircases

Common types of steel staircases include:

- Straight Staircases – Simple structures suitable for larger spaces, providing a direct and efficient way between floors.

- Industrial Staircases – Featuring steel grating treads, commonly used in factories and warehouses for durability and practicality.

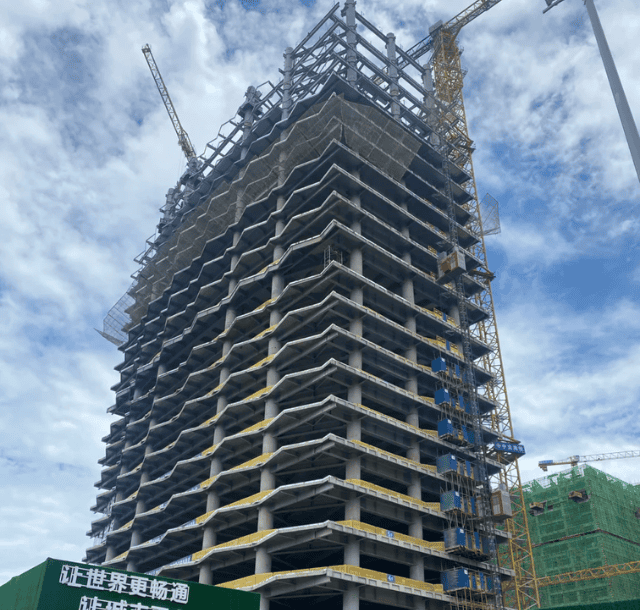

- Emergency Staircases – Designed for evacuation purposes, typically located on the exterior of buildings for quick and safe exit in emergencies.

- Mezzanine Staircases – Designed to connect a mezzanine or intermediate level with the main floor, offering a compact and efficient solution for multi-level spaces.

- Spiral Staircases – Space-saving designs ideal for compact areas or decorative purposes, with a distinctive, curved shape.

- Curved Staircases – Aesthetically pleasing and functional, often used in commercial or public spaces for a unique design statement.

- Dual Staircases – Two staircases that mirror each other, often used in large commercial or public buildings, allowing for increased traffic flow and a symmetrical aesthetic.

- Cantilevered Staircases – These staircases have steps that seem to float, supported only by one side, creating a sleek, modern appearance, often used in high-end residential or contemporary commercial spaces.

- Floating Staircases – A visually striking design where each step appears to float, with hidden supports. These are ideal for luxury homes and high-design commercial spaces.

Fabrication and Installation of Steel Staircases

Fabrication Process

- Based on design drawings, materials are cut, shaped, and processed.

- The steel undergoes surface treatment, such as sandblasting, galvanizing, or applying anti-corrosion coatings.

- Components are pre-assembled in the factory to ensure dimensional accuracy and quality.

Installation Steps

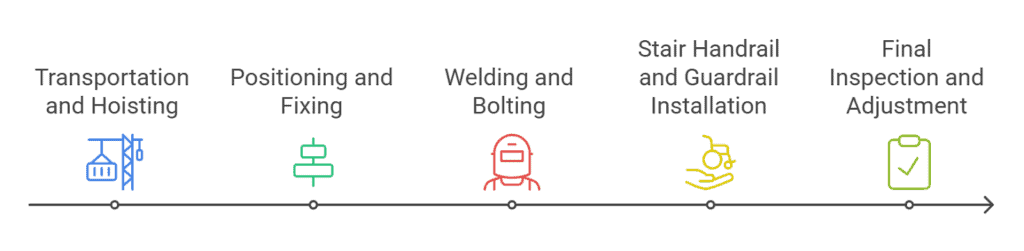

1. Transportation and Hoisting

Prefabricated components are transported to the construction site and hoisted using cranes or other lifting equipment.

In confined spaces, precise hoisting paths are planned to avoid collisions with other structures or equipment. For complex designs (e.g., spiral staircases), segmented hoisting is used, starting with the support structure.

2. Positioning and Fixing

Components are accurately placed using laser levels and total stations to ensure proper alignment. Temporary supports may be used to hold components in place during welding or bolting.

3. Welding and Bolting

Welding is performed by certified welders to meet standards (e.g., AWS D1.1). High-strength bolts are used for bolted connections, with pre-tension checks conducted as per specifications.

4. Handrail and Guardrail Installation

Handrails and guardrails are installed to meet safety standards (e.g., handrail height of 90-110 cm, guardrail spacing not exceeding 11 cm).

5. Final Inspection and Adjustment

A comprehensive quality check is performed, including structural stability, connection strength, and surface finish, to ensure compliance with design and safety requirements.

Safety and Compliance Requirements

To ensure the safety of steel staircases, design and construction must adhere to relevant standards and regulations. Key safety requirements include:

1. Load Capacity

Industrial steel staircases must have a minimum load capacity of 4.0 kN/m² to meet safety demands in high-traffic areas. Adequate load capacity ensures stability under full load, preventing structural failure.

2. Tread Dimensions

Tread height should be less than 18 cm, and width should exceed 22 cm. Ergonomically designed treads enhance user comfort and reduce the risk of tripping.

3. Handrails and Guardrails

Handrail height should be 90-110 cm, with guardrail spacing not exceeding 11 cm. Proper dimensions prevent falls and ensure user safety.

4. Anti-Slip Design

Tread surfaces must be treated for slip resistance, especially in wet or oily environments. Anti-slip designs significantly reduce the risk of accidents.

5. Fire Safety

In high-rise or public buildings, staircases must meet fire safety standards, with fire-resistant coatings applied if necessary. Fire safety measures delay the spread of flames, providing critical evacuation time.

6. Emergency Evacuation

Emergency staircases must have sufficient width (typically at least 1.1 meters) and be equipped with emergency lighting and signage. Proper evacuation design ensures safe and swift exits during emergencies.

Unlock Space, Safety, and Style with Our Steel Staircases

Steel staircases are a vital element in steel building designs, but they often come with challenges—whether it’s choosing the right type of staircase for limited spaces, ensuring durability and safety in high-traffic environments, or balancing aesthetic appeal with cost-efficiency.

Our expert team is here to help you overcome these obstacles. We offer comprehensive services, including consulting on the best steel staircase design options, custom solutions tailored to your needs, and ensuring compliance with safety regulations. We can guide you through the pros and cons of various types of staircases, from straight and spiral to industrial and emergency staircases, while providing transparent pricing and cost-effective solutions.

Whether you need design advice, installation guidance, or material recommendations, don’t hesitate to reach out. Let’s build a trusted partnership and help you create steel staircases that are both safe and visually appealing for your project!